Deep Groove Ball Ukuzala 6300 series

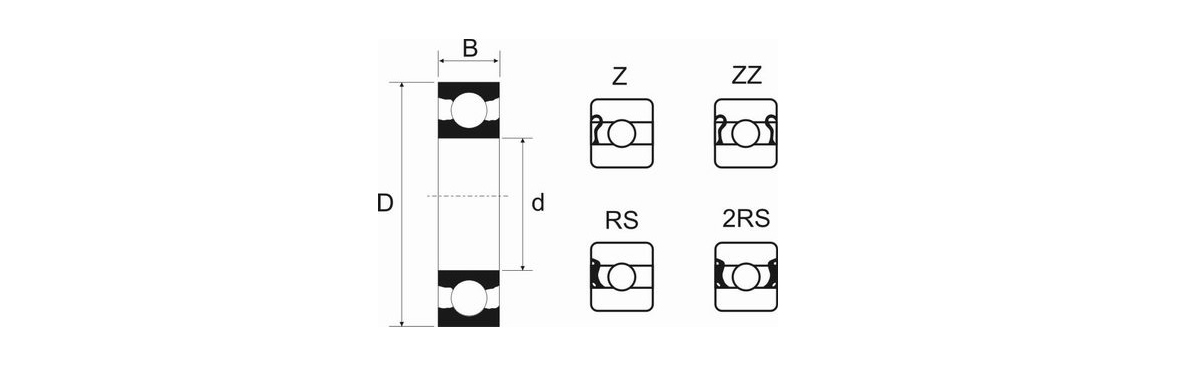

UKUNIKELA IIPARAMETHA

Umqolo omnye weebheringi zebhola zegroove ziza kuthotho lwamanani amathathu amele ubungakanani kunye nomthamo womthwalo wento nganye.Bazi:

I-6000 Series-Iibhodi zokuKhanya ezongezelelweyo zeBhola-Ifanelekile kwizicelo zendawo ezilinganiselwe

6200 Series - Light Series Ball Bearings - Ulungelelwaniso phakathi kwendawo kunye nomthwalo umthamo

6300 Series - Medium Series Ball Bearings - Ilungele izicelo umthamo onzima

Iiparameters ze-6300 series zimi ngolu hlobo lulandelayo:

| Ukubamba iNombolo. | Isazisi | OD | W | Umlinganiselo womthwalo(KN) | Iparamitha yeBhola yentsimbi | Isantya esiphezulu | Ubunzima beyunithi | |||

| d | D | B | Unamandla | I-Static | Hayi. | Ubungakanani | Gcoba | I-oyile | ||

| mm | mm | mm | Cr | Kor | mm | r/min | r/min | kg | ||

| 6300 | 10 | 35 | 11 | 8.20 | 3.50 | 6 | 7.1440 | 23000 | 27000 | 0.053 |

| 6301 | 12 | 37 | 12 | 9.70 | 4.20 | 6 | 7.9380 | 20000 | 24000 | 0.060 |

| 6302 | 15 | 42 | 13 | 11.40 | 5.45 | 7 | 7.9380 | 17000 | 21000 | 0.082 |

| 6303 | 17 | 47 | 14 | 13.50 | 6.55 | 7 | 8.7310 | 16000 | 19000 | 0.115 |

| 6304 | 20 | 52 | 15 | 15.90 | 7.90 | 7 | 9.5250 | 14000 | 17000 | 0.144 |

| 6305 | 25 | 62 | 17 | 21.20 | 10.90 | 7 | 11.5000 | 12000 | 14000 | 0.232 |

| 6306 | 30 | 72 | 19 | 26.70 | 15.00 | 8 | 12.0000 | 10000 | 12000 | 0.346 |

| 6307 | 35 | 80 | 21 | 33.50 | 19.10 | 8 | 13.4940 | 8800 | 10000 | 0.457 |

| 6308 | 40 | 90 | 23 | 40.50 | 24.00 | 8 | 15.0810 | 7800 | 9200 | 0.633 |

| 6309 | 45 | I-100 | 25 | 53.00 | 32.00 | 8 | 17.4620 | 7000 | 8200 | 0.833 |

| 6310 | 50 | 110 | 27 | 62.00 | 38.50 | 8 | 19.0500 | 6400 | 7500 | 1.070 |

| 6311 | 55 | 120 | 29 | 71.50 | 45.00 | 8 | 20.6380 | 5800 | 6800 | 1.370 |

| 6312 | 60 | 130 | 31 | 82.00 | 52.00 | 8 | 22.2250 | 5400 | 6300 | 1.700 |

| 6313 | 65 | 140 | 33 | 92.50 | 60.00 | 8 | 24.0000 | 4900 | 5800 | 2.080 |

| 6314 | 70 | 150 | 35 | 104.00 | 68.00 | 8 | 25.4000 | 4600 | 5400 | 2.520 |

| 6315 | 75 | 160 | 37 | 113.00 | 77.00 | 8 | 26.9880 | 4300 | 5000 | 3.020 |

| 6316 | 80 | 170 | 39 | 123.00 | 86.50 | 8 | 28.5750 | 4000 | 4700 | 3.590 |

| 6317 | 85 | 180 | 41 | 133.00 | 97.00 | 8 | 30.1630 | 3800 | 4500 | 4.230 |

| 6318 | 90 | 190 | 43 | 143.00 | 107.00 | 8 | 32.0000 | 3600 | 4200 | 4.910 |

| 6319 | 95 | 200 | 45 | 153.00 | 119.00 | 8 | 34.0000 | 3300 | 3900 | 5.670 |

| 6320 | I-100 | 215 | 47 | 173.00 | 141.00 | 8 | 36.5120 | 3200 | 3700 | 7.200 |

UKUGQIBELA UKWAKHIWA

UKUTHWALA IZINTO

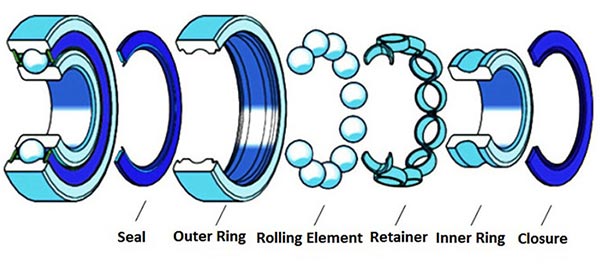

Ukusebenza kunye nokuthembeka kweebheringi eziqengqelekayo zichaphazeleka kakhulu kwizinto ezenziwe ngamacandelo okuthwala i-BXY amakhonkco kunye neebhola zenziwe ngekhwalithi ephezulu ye-GCr15 vacuum-degassed bearing steel. ummeli ophethe intsimbi njengetshathi eboniswe ngezantsi:

| IKhowudi esemgangathweni | Izinto eziphathekayo | Uhlalutyo(%) | ||||||

| C | Si | Mn | Cr | Mo | P | S | ||

| GB/T | GCr15 | 0.95-1.05 | 0.15-0.35 | 0.25-0.45 | 1.40-1.65 | ≦0.08 | ≦0.025 | ≦0.025 |

| I-DIN | 100Cr6 | 0.95-1.05 | 0.15-0.35 | 0.25-0.45 | 1.40-1.65 | ≦0.030 | ≦0.025 | |

| I-ASTM | 52100 | 0.98-1.10 | 0.15-0.35 | 0.25-0.45 | 1.30-1.60 | ≦0.10 | ≦0.025 | ≦0.025 |

| I-JIS | SUJ2 | 0.98-1.10 | 0.15-0.35 | ≦0.50 | 1.30-1.60 | ≦0.025 | ≦0.025 | |

UMBONISO WEMVELISO

UKWENZA ISICELO

I-deep groove ball bearing ifanelekile kuzo zonke iintlobo zokuhanjiswa komatshini, i-factory exhasayo imoto, izixhobo zokufaneleka, izixhobo zonxibelelwano, izixhobo kunye neemitha, izixhobo ezichanekileyo, izixhobo zokuthunga, izixhobo zendlu, izixhobo zonyango, izixhobo zokuloba kunye namathoyizi, njl.

UKUNIKELA IMIYALELO

Iibheringi zigqunywe nge-agent ye-antirust kwaye zipakishwe kwaye zishiye umzi-mveliso.Inokuhlala iminyaka ukuba igcinwe ngokufanelekileyo kwaye ipakishwe kakuhle.

1. Gcina kwindawo eneqondo lokushisa elingaphantsi kwama-60%;

2. Musa ukubeka ngokuthe ngqo emhlabeni, ubuncinane i-20 cm ukusuka emhlabeni kwiqonga elibekwe kakuhle;

3. Nika ingqalelo ukuphakama xa ubeka, kwaye ukuphakama kwe-stacking akufanele kudlule i-1 mitha.